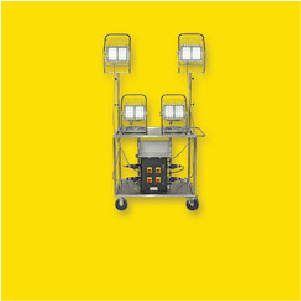

Digital Controller

High speed and high accuracy

- High speed control: 50 ms input sampling

- Indication accuracy: 0.1%

- 5-digit display can show 0.01°C

- Accepts various input: thermocouple, RTD, voltage, or current

- 9 DIs, 9 DOs, and 2 AOs

- Variety of functions: RS-485, T-Link, math function, ramp soak, transmitter power supply, complete templates

- Shallow body and front waterproof structure

- Easy parameter setting thanks to the loader software

Ideal for process control of temperature, pressure, and flow.

Categories: Temperature Controllers, FUJI ELECTRIC

Description

| Power supply voltage | 100–240 V AC, 50/60 Hz |

|---|---|

| Power consumption | ≤ 20 VA (at 220 V) |

| Input | Thermocouple, RTD, DC voltage/current |

| Indication accuracy | ±0.1% FS |

| Sampling rate | 50 ms |

| Input correction | zero and span adjustment, square root extraction, filter |

| Auxiliary analog input | 1 point among 1–5 V, 0–5 V, 0–10 V For motor-operated valve control: potentiometer 100 Ω–10 kΩ |

| Digital input | 4 points or 9 points No-voltage contact or transistor input |

| Math function | Flow rate compensation with temperature and pressure, average, Max/Min selector, input switching |

| Ramp soak | 64 steps, 31 patterns |

| Control types | Basic, heating/cooling control, motorized valve control |

| Control output | Relay contact, SSR/SSC drive, 4–20 mA DC, or motorized valve control output |

| Digital output | 2 points or 9 points, SPST or SPDT |

| Analog transfer output | 4–20 mA DC, up to 2 points |

| Transmitter power supply | Power supply for 2-wire transmitter (17–30 V DC) |

| Control method | 2-degrees-of-freedom PID with auto tuning |

| Control template | Pre-installed input/output setting and calculation blocks |

| Control mode | Auto, manual, or remote |

| Alarm | Up to 8 points |

| Alarm type | PV (high/low, absolute, deviation, zone, change rate), SV high/low, device error, hold, latch, excitation/non-excitation |

| Alarm output | can be allocated to digital output |

| Communication (option) | RS-485 (Modbus) |

| Front keys | 4 keys (including user-defined key), with key lock function |

| Display | LED, 5-digit |

| Front structure | IP66, NEMA-4X equivalent |

| Dimensions and weight | 96 (W) × 96 (H) × 81.5 (D) mm, approx. 500 g |

| Mounting method | Panel mount |

| External wiring terminals | M3 screw terminal |

| Parameter loader software | Supported OS: Windows 2000, Windows XP, Windows 7 Empty hard-disk capacity: 100 MB or more Dedicated USB cable is option. Software can be used via RS-485 (Modbus) network. |