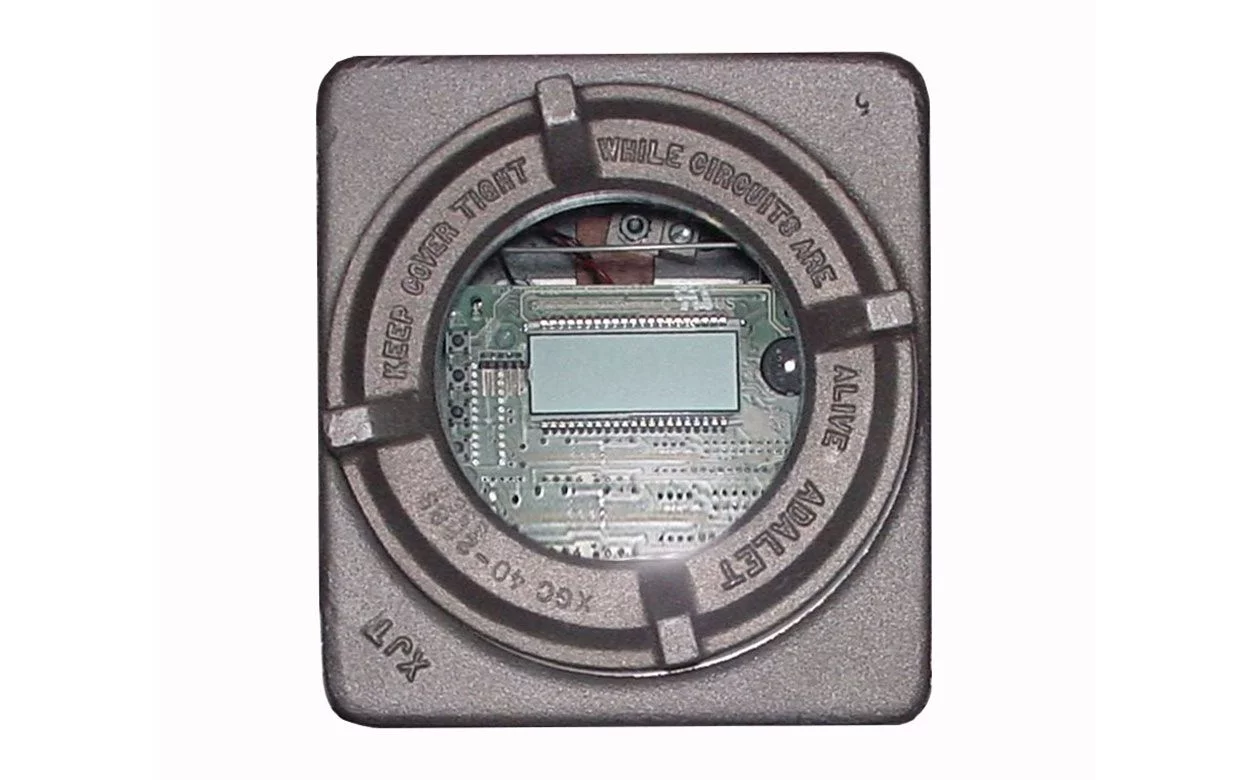

508 UV-VIS™ PROCESS ANALYZER

GUIDED WAVE™ UV-VIS Full Spectrum Process Analyzer

Description

RELIABLE FULL SPECTRUM UV-VIS PROCESS ANALYZER

For Remote Single or Multi-Channel Spectroscopic Analysis

Our GUIDED WAVE™ 508 UV-VIS™ Full Spectrum Process Analyzer is a single or multi-channel, fiber optic, UV-VIS spectrometer system designed for use in process environments. Configurable with up to 4 channels, the 508 UV-VIS comes in a NEMA 4x enclosure with built-in thermal control to ensure the most consistent performance possible while in 24/7 service mode.

Up to 16 parameters may be monitored on each channel making it suitable for many applications in chemical and polymer plants, refining and petrochemical, pharmaceuticals and other specialty chemicals, paints and varnishes, adhesives, wastewater management, biotech, etc. It has a built-in computer control unit with optional touch screen for convenient user interface.

FEATURES

- High sensitivity 2048 Pixel Diode Array Spectrometer

- Built-in compact Xe flash UV-VIS light source

- Rapid data collection

- Built-in Instrument Control Unit with door mounted touch screen

- Analyzer control program developed in LabView™ featuring customizable settings and trending capability

- Modbus Ethernet TCP/IP communications with built-in event setup

- Optional Opto-22 panel and communications for 4-20 mA analog and discrete interfacing

- 16 Analog Inputs for temperature & pressure correction of vapor/gas streams (requires Modbus or OPTO 22)

- Compatible with our other proven probes and flow cell products

- Fully insulated NEMA 4 or 4X enclosure with built in Internal Thermal Control

- Full spectrum scanning, 200 nm to 850 nm

- Multi-channel design from 1 to 4 channels

BENEFITS

The GUIDED WAVE 508 UV-VIS Full Spectrum Process Analyzer offers several benefits:

- Accurate and reliable measurements: The analyzer uses a full spectrum of UV-VIS light to provide highly accurate and reliable measurements of multiple parameters simultaneously.

- Non-destructive testing: The analyzer uses non-destructive testing methods, which means that samples do not need to be destroyed in the measurement process.

- Real-time monitoring: The analyzer provides real-time monitoring of multiple parameters, allowing for immediate adjustments to be made to the process.

- High sample throughput: The analyzer has a high sample throughput, allowing for rapid analysis of large numbers of samples.

- Easy to use: The analyzer is easy to use and can be integrated into existing process control systems, making it a convenient and efficient tool for process monitoring and control.

- Cost-effective: The analyzer is a cost-effective solution for process monitoring and control, offering long-term savings by reducing waste and improving product quality.

INDUSTRIES

Here is a list of industries that use the GUIDED WAVE 508 UV-VIS Full Spectrum Process Analyzer:

- Chemical production

- Petrochemicals

- Refining

- Biofuels

- Pharmaceutical manufacturing

- Food and beverage production

- Polymer production

- Environmental monitoring and testing

APPLICATIONS

- L*a*b* and other color coordinates

- Solvent recovery purity

- Maleic acid in tetrahydrofuran (THF)

- Trace (ppm level) impurities in wash water; Clean-In-Place for Pharma

- Polynuclear aromatics (PNAs) in middle distillates

- Phenol in cyclohexanone

- Sodium hypochlorite in bleach solutions

- Aromatics in monomers

- Benzene in cyclohexane

- Saybolt or ASTM color of diesel and jet fuels

- Toluene diisocyanate in polyurethane

- UV inhibitors in polymers

- Antioxidants in polymers and plastics

- Color and clarity of varnishes

- Halogens and various halogenated compounds in vapor streams

- Sorbic acid in water

- Ferrous chloride in acid

- Acetonitrile purity

- Hypochlorous acid