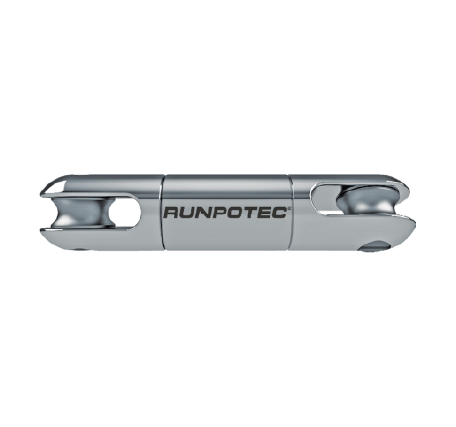

AXIAL PROCESS FLOW CELL

GUIDED WAVE™ Long Path Flow Cell for Process UV / VIS / NIR Photometry

Description

HIGHLY EFFICIENT & RELIABLE

A Long Path Flow Cell for Process UV / VIS / NIR Spectroscopy

Flow cell performance strongly affects the overall system performance of a process analyzer. High optical efficiency and low sensitivity to environmental factors are essential to sensitive, reliable measurements. Best system performance requires a flow cell that is insensitive to vibration, temperature and pressure changes. Stable performance is especially difficult to achieve when a long-path flow cell is dictated by low limits of detection. Our GUIDED WAVE™ Axial Process Flow Cell gives path-lengths of 30mm to 100 mm with exceptional immunity to environment.

RESISTANCE TO ENVIRONMENTAL INFLUENCES

The standard GUIDED WAVE Axial Process Flow Cell is constructed from 316L stainless steel. It can also be made from other materials depending upon specific application requirements, such as Hastelloy C-276. Elastomeric seals prevent leakage and protect the Axial Flow Cell’s vital internal optics. The process and processing environment dictate the actual O-ring material that is best suited for the application. Suitable O-ring materials must be specified to meet your process chemistry and safety requirements. Common materials, such as Viton, Kalrez®, EPDM, etc., are readily available.

EFFECTIVE FOR LOW LEVEL DETECTION

High optical throughput and exception stability make the GUIDED WAVE Axial Process Flow Cell particularly effective in achieving low levels of detection. For example, water levels less than 100 ppm can be routinely measured in organics when the Axial Flow Cell is used with a good quality photometer or spectrometer. Similarly, the lowest APHA color values are easily measured, and the onset of yellowness is easily detected.

EXCEPTIONAL LIGHT TRANSMISSION

Like our other GUIDED WAVE optical probes, the Axial Flow Cell provides exceptional optical performance. Typically, the longer the path length the lower the transmission. Where the Axial Process Flow Cell is concerned, its peak transmission exceeds 30% which is considerably higher than the competition. That means more signal, lower measurement noise and lower limits of detection!

FEATURES – A SIMPLE, SERVICEABLE DESIGN

- High optical throughput for low noise spectroscopy

- Suitable for liquids and vapors

- Cleanout ports at each window make cell maintenance a snap

- Collimated beam for consistently accurate measurements

- Reproducible pathlength permits servicing in the field

- Compatible with 200 through 600-micron fiber

- Compatible with all fiber optic based UV-VIS-NIR instruments

- 9 mm diameter optics minimize divergence losses

- O-ring sealed optics to prevent ambient moisture infiltration

- Compatible with all of our other Guided Wave analyzers and many other analyzer brands

WHY CHOOSE AN AXIAL FLOW CELL

Perhaps the most critical decision in designing a successful online analyzer system is the selection of the sample interface. While an insertion probe approach can often reduce installation costs, sometimes safety, servicing, and/or sample conditioning requirements make it necessary to integrate a sampling loop or slip stream. The Axial Process Flow Cell is preferred whenever (a) direct insertion probes are inappropriate and (b) the required optical path length is 30 mm or greater. The Axial Process Flow Cell is a convenient, compact, rugged sample interface that is easy to install and even easier to service. The Axial Process Flow Cell is available in our standard pathlengths 30, 50, 75, and 100 mm.

SPECIFICATIONS: AXIAL FLOW CELL

| Product Name | Axial Process Flow Cell |

|---|---|

| Optical Pathlength | 30; 50; 75; 100 mm |

| Spectral Range | UV-VIS (200 – 600 nm); NIR (600- 2100 nm) |

| Fiber Connector | SMA 905 |

| Optical Efficiency | ≥30% transmission from 800 to 1650 nm for pathlengths ≤50 mm (%T) |

| Temperature Range | ≤300 °C (O-ring material dependent) |

| Pressure Range | 0 to 500 psi [3450 kPa] |

| Body Material | 316L SS standard; Hastelloy C-276, others available on request |

| O-Ring Material | Viton, EPDM, Kalrez, silicon, other materials available upon request |

| Process Connection | Nominal 1/4 inch tube connection (Swagelok fittings standard) |

APPLICATIONS

- Crude Oil Processing

- Water in Solvents

- Polyurethane Synthesis

- Caustic in Water

- Online Monitoring of Saybolt Color with a ClearView db Photometer

- Probes and Flow Cells for Extreme Environments

- Learn how our GUIDED WAVE RUGGED PROBES & FLOW CELLS MEET REFINERY REQUIREMENTS.

- Interested in learning more about our GUDIED WAVE PROBES & FLOW CELL SAFETY STANDARDS?

- Water Analysis in an Alcohol-Brine Solution with a ClearView db Photometer

- Water in Acetic Acid & p-Xylene with a ClearView db Filter Photometer

- Styrene, Acrylonitrile & Methyl-Ethyl-Ketone (Mek) for Online Control on a Styrene Tower

- Ensure Proper Ethylene Glycol Production Yields using NIR Technology

- Improve Yield During Diisocyanate & Urethane Synthesis

- Fast Reliable Measurements of Polyurethanes

- Probes & Flow Cells for Extreme Environments

- Probes and Flow Cells for High Temperature and Hazardous Polymer Measurements

- Inline Transmission Probe For FT-NIR Measurements

- Online Monitoring of APHA Color (ASTM D1209) with a ClearView db Photometer