CLEARVIEW® DB HYDROGEN PEROXIDE VAPOR ANALYZER SYSTEM

GUIDED WAVE™ VIS-NIR Dual-Beam Photometer

Description

HYDROGEN PEROXIDE VAPOR ANALYZER SYSTEM

Turnkey solution for the measurement of hydrogen peroxide and water (H2O2 and H2O) concentrations in vapor phase

Our GUIDED WAVE™ ClearView® Hydrogen Peroxide Vapor Analyzer System is a simple turnkey solution for the measurement of hydrogen peroxide and water (H2O2 and H2O) concentrations in vapor phase. These are both measured together because they are codependent. The analyzer operates in real time, which takes the guesswork out of determining the H2O2 and H2O concentrations during cycle development and throughout the actual sterilization cycle. The user gains continuous, accurate data for documentation and validation.

WHY IS IT IMPORTANT TO MEASURE HYDROGEN PEROXIDE AND WATER (H2O2 AND H2O) CONCENTRATIONS IN VAPOR PHASE?

Measuring hydrogen peroxide (H2O2) and water (H2O) concentrations in vapor phase is important for several reasons:

- Process control: H2O2 and water vapor concentrations are important parameters in several industrial processes, including sterilization, disinfection, and semiconductor manufacturing. Measuring these concentrations can help ensure process efficiency, consistency, and product quality.

- Regulatory compliance: Several industries, including healthcare and pharmaceuticals, have regulations and guidelines for H2O2 and water vapor concentrations in the air. Measuring these concentrations is necessary to ensure compliance with regulations and to protect public health.

- Environmental monitoring: H2O2 and water vapor can be emitted from industrial processes and can impact the environment. Measuring these concentrations can help identify potential environmental impacts and ensure compliance with environmental regulations.

- Occupational safety: H2O2 is a strong oxidizing agent that can be hazardous to human health if inhaled or ingested in high concentrations. Measuring the concentration of H2O2 in vapor phase can help ensure that occupational exposure limits are not exceeded and workers are not exposed to unsafe levels.

OUR SYSTEM BENEFITS

- Real-time hydrogen peroxide sterilant gas monitoring

- Proven technology works in vacuum and atmospheric conditions

- H2O2 and H2O concentration by direct optical measurements

- Vital for resistometers and HPV cycle development

- Independent reference for HPV load production

- Optical RH and relative saturations measurement

LOW PRESSURE MONITORING WITH ACCURATE, RELIABLE RESULTS

Unlike chemical sensors, the GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System is able to measure H2O2 and H2O concentrations in vapor phase under ambient or vacuum conditions. Many processes use low pressure in the sterilization process to ensure penetration of product packaging. This system allows you to monitor these cycles so you can determine that the correct concentration of H2O2 and H2O were present during each cycle.

- Rapid response

- Multiple sample points on one analyzer

- Not subject to sensor poisons or analyte degradation

- Built-in validation available

PROVEN TECHNOLOGY

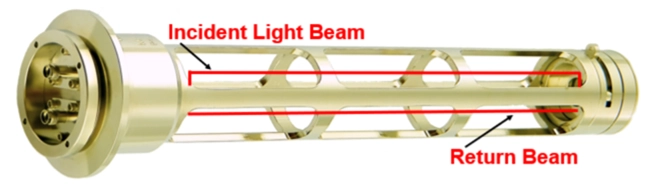

Our GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System utilizes a multi wavelength ClearView db filter photometer analyzer platform. Optimal wavelengths for H2O2 and H2O were selected to produce a simple yet rugged and reliable analyzer for this dedicated application. This new design uses fixed wavelength filter technology, yet still incorporates dual beam design for stability and accuracy. Fiber optic cables take the NIR light energy to the probe in the isolator and returns the non-absorbed light energy back to the analyzer – the optical equivalent of vapor sampling. The analyzer measures as low as 0.1 mg/L of H2O2 and 1.0 mg/L of H2O. With the addition of a temperature value, relative humidity and relative saturation measurements can be made.

APPLICATIONS

Here are some applications that use the GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System:

- Microbial contamination control

- Bioreactor and fermenter monitoring

- Quality control in pharmaceutical manufacturing

- Research and development in biotechnology and life sciences

- Medical device manufacturing

- Food and beverage processing

- Environmental monitoring and testing

INDUSTRIES

The GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System is primarily used in:

- Pharmaceutical manufacturing industry

- Sterile production areas, such as cleanrooms and isolators

- Used in other industries where hydrogen peroxide is used for sterilization, such as medical device manufacturing, biotechnology, and research laboratories.

The system is designed to measure the concentration of hydrogen peroxide vapor in real-time, providing critical information for the decontamination process. Hydrogen peroxide vapor is commonly used as a sterilization agent in these environments to ensure the elimination of microbial contamination. It’s a non-invasive and non-destructive tool that provides rapid, accurate, and reliable analysis of hydrogen peroxide vapor concentration. It helps to ensure that the decontamination process is effective and that the sterile environment is maintained.

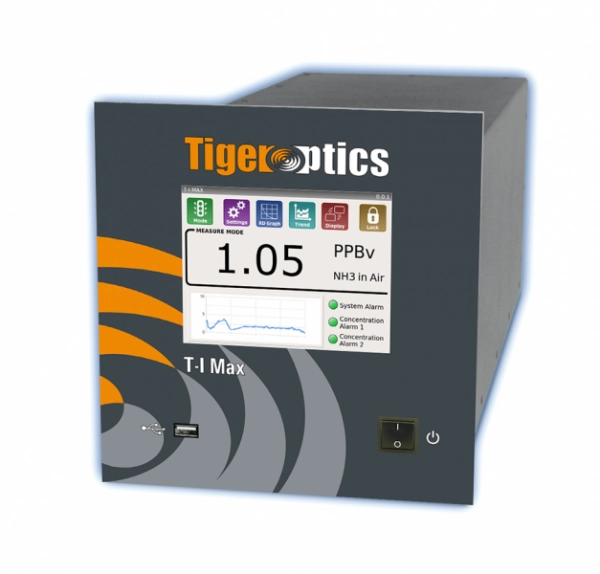

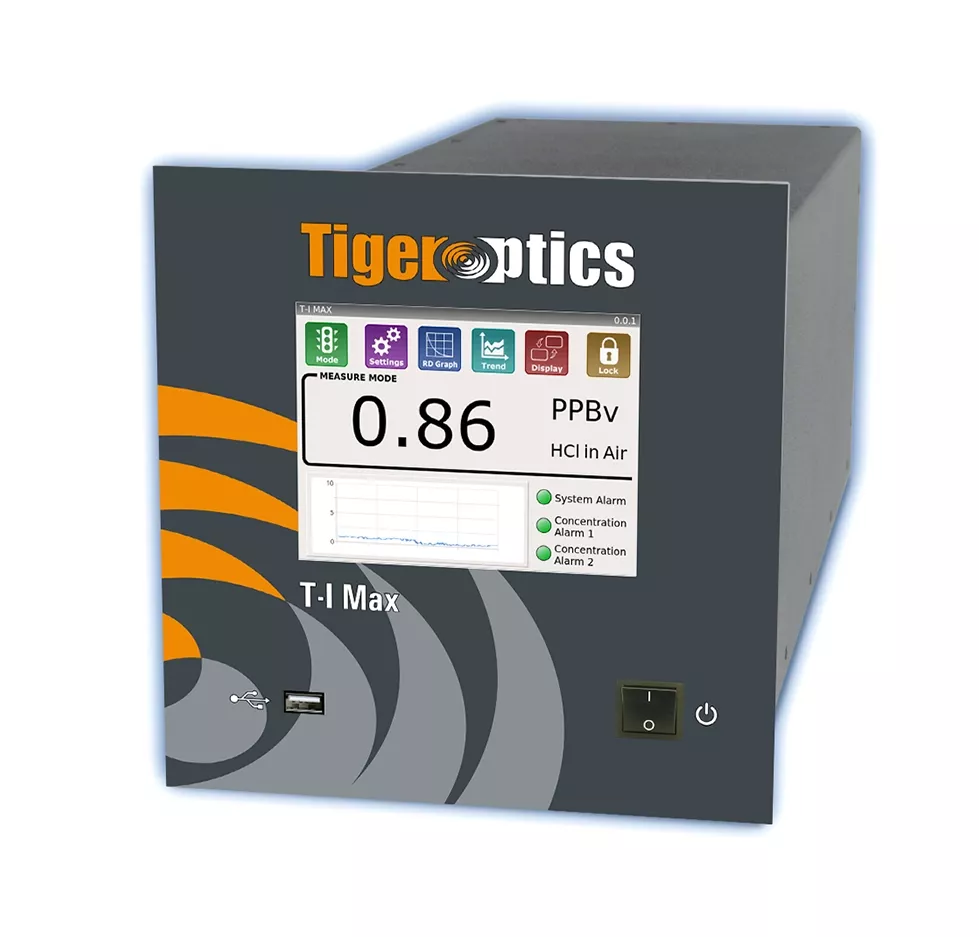

EASY OPERATION AND CONTROL

The GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System is controlled via its touch screen or remotely via Ethernet (Modbus TCP/IP). All of the analytical calculations are encoded in the software. The complete system consists of a CLEARVIEW HVP Analyzer, one or two G-SST probes, and a pair of fiber optic cables for each probe. The analyzer is pre-calibrated at the factory. No programming is required by the user. Start-up requires powering the analyzer, connecting the probe or probes via the fiber optic cables, taking a ZERO reading in the dehumidified isolator and the H2O2 and H2O concentration measurements may begin.

ANALYZER OPTIONAL ENCLOSURES

Typically for medical, pharmaceutical and food industries, the GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System may be housed in a stainless-steel enclosure. Other enclosure options are available, such as, painted carbon steel, explosion-proof or purged depending on area classification requirements.

USER PROGRAMMABLE FEATURES

• Password protection for configuration changes

• Sampling time: 1 second minimum. User settable

• Reporting units: mg/L or ppm-V

ANALYZER SYSTEM ACCESSORIES AND OPTIONS

- 2nd channel for additional independent sampling point

- Custom length fiber cables

- KF or Tri-clover® flanged fiber feed throughs and dual fiber feed throughs

- Annual factory calibration service available

- Universal power supply (110-240 VAC converter to 24 VDC)

- Custom calibration for elevated temperature on request

FIBER CABLE

• 500 µm Ultra Low-OH fiber with stainless steel SMA-905 connectors

• Kevlar® protected or armored cables available

THE SMART CHOICE FOR RELIABLE MEASUREMENT

Our GUIDED WAVE ClearView Hydrogen Peroxide Vapor Analyzer System delivers accurate, real time H2O2 and H2O measurement results. Its long-term stability and no maintenance requirements make it a cost effective, smart choice to help optimize production and ensure product quality ultimately enhancing profitability. As an ISO 9001 certified company, we maintain expert technical support and responsive global service for the lifetime of the system.