CO-REKT™

TIGER OPTICS™ CRDS Analyzer for Trace Level Impurity for Hydrogen

Description

RDS LASER-BASED ANALYZER

CLASS I DIV II FOR HYDROCARBON FEEDSTOCKS AND SYNGAS

Just in time to meet the growing demand for high-quality hydrogen feedstock, our TIGER OPTICS™ CO-rekt™ trace-level analyzer for hydrogen brings the renowned benefits of our Cavity Ring-Down Spectroscopy to your HyCO and SMR plants. This powerful, proven technology offers safe, fast and stable performance that allows you to efficiently manage your PSA beds to maximize yields and minimize contamination. It’s dynamic range spans over four orders of magnitude, from parts-per-billion to parts-per-million.

BENEFITS

- Drift-free performance: Avoid the downtime and labor cost tied to older technology’s need for frequent calibration. It is so stable that it does not require calibration. No longer need to store and to manage calibration cylinders or pay for complex sampling systems. And remember, the less need for intervention, the less that can go wrong.

- No consumables and spare parts: The CO-rekt is all solid state. Lose those pesky choppers and save on repair costs, as well as inventory management and storage space.

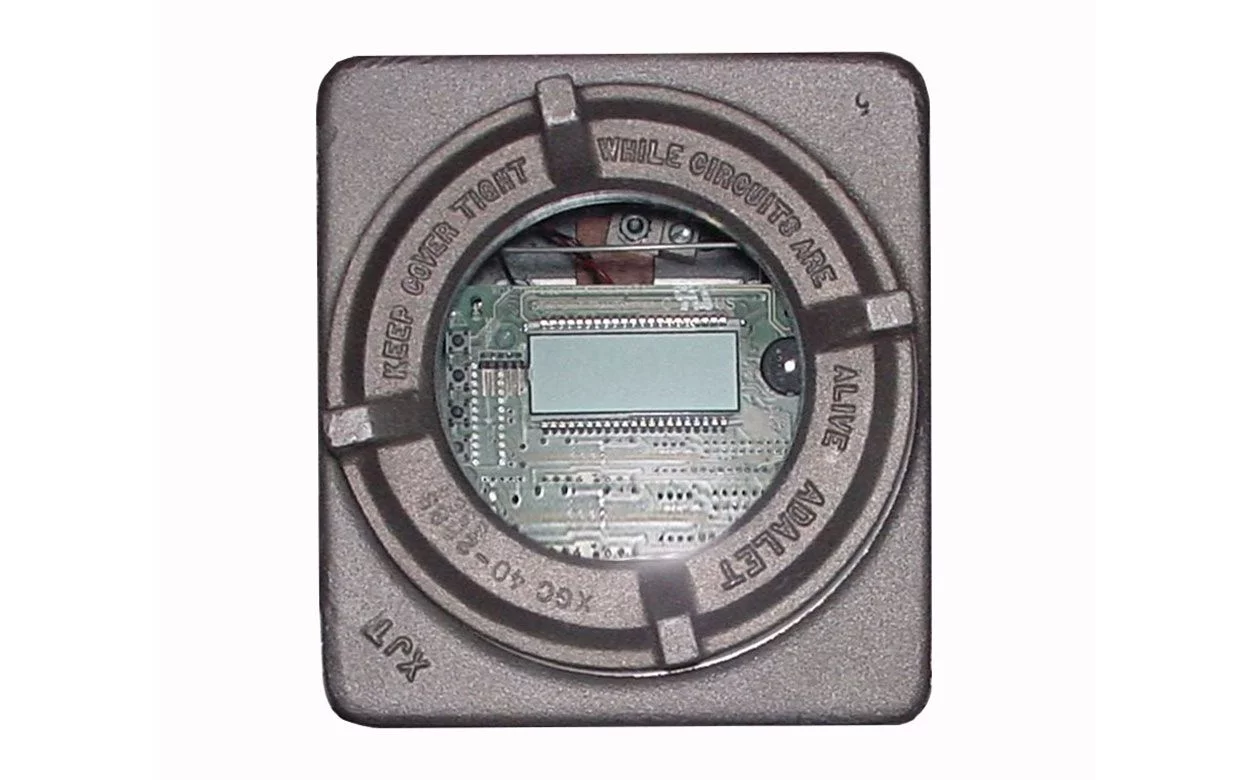

- Packaged for plant use: With Class I, Div. 2 certification, the CO-rekt combines a purged NEMA enclosure with a space-saving wall-mount configuration designed for narrow instrument sheds.

- Insensitive to vibration: No more plant trips triggered by the mere slam of a door to the instrument shed. Protects up-time bonuses and avoids fines.

- Continuous online monitoring

- Wide dynamic range

- Excellent sensitivity with ppb level detection limits (LDL)

- Fast speed of response

Our analyzers are impervious to vibration and proven to stand up to long-term use in industrial applications. Designed in collaboration with one of the world’s leading hydrogen manufacturers, the CO-rekt is guaranteed to increase uptime and decrease risk. Freedom from calibration and low cost of ownership allows users to operate with confidence and ease in the field.

APPLICATIONS

- Air Separation Units & Nitrogen Plants

- High-Purity Gases & Systems

- hyCO Plants

- SMR Plants

- Syngas & Fuel Gas Production

HYDROGEN PURITY

Sourcing high-purity hydrogen is critical to many diverse industrial applications where impurities impair yields. It is required for:

- Chemical production

- Metal refining

- Oil refining

- Food processing

- Semiconductor fabrication

CLICK + TO SEE: DETECTION CAPABILITY & SPECIFICATIONS

DETECTION CAPABILITY

| Detection and Matrix | Range | LDL (3σ) | Precision (1σ) @ zero |

|---|---|---|---|

| CO in H2 | 0 − 2000 ppm | 150 ppb | 50 ppb |

| CO2 in H2 | 0 − 1500 ppm | 500 ppb | 170 ppb |

| H2O in H2 (low range) | 0 − 16 ppm | 1.0 ppb | 0.4 ppb |

| H2O in H2 (high range) | 0 − 1750 ppm | 7.5 ppb | 2.5 ppb |

| CH4 in H2 (low range) | 0 − 8 ppm | 1.6 ppb | 0.6 ppb |

| CH4 in H2 (high range) | 0 − 100 ppm | 7 ppb | 2.5 ppb |

SPECIFICATIONS

| Performance | |

|---|---|

| Operating range | See Detection Capability table |

| Detection limit (LDL, 3σ/24h) | See Detection Capability table |

| Precision (1σ, greater of) | ± 0.75% or 1/3 of LDL |

| Accuracy (greater of) | ± 4% or LDL |

| Speed of response | < 3 minutes to 90% |

| Environmental conditions | 10°C to 40°C, 30% to 80% RH (non-condensing) |

| Storage temperature | -10°C to 50°C |

| Gas Handling System and Conditions | |

| Wetted materials | 316L stainless steel (optional corrosion-resistant material), 10 Ra surface finish |

| Gas connections | 1/4” compression fittings inlet, outlet and purge |

| Leak tested to | 1 x 10-9 mbar l / sec |

| Inlet pressure | 10 − 125 psig (1.7 − 9.6 bara) |

| Flow rate | Up to 1.8 slpm (gas dependent) |

| Sample gases | Nitrogen, hydrogen and syngas (inquire for custom matrices) |

| Gas temperature | Up to 60°C |

| Dimensions, H x W x D | |

| Standard sensor (in NEMA 4X enclosure) | 17.5″ x 22″ x 15.2″ (445 mm x 559 mm x 386 mm) |

| Weight | |

| Standard sensor | 82 lbs (37.2 kg) |

| Electrical and Interfaces | |

| Alarm indicators | 2 user programmable, 1 system fault, Form C relays |

| Power requirements | 90 − 240 VAC, 50/60 Hz |

| Power consumption | 40 Watts max |

| Signal output | Isolated 4−20 mA per sensor |

| User interface | 5.7” LCD touchscreen |

| Certification | |

| Class I, Div. 2, Groups B, C & D | |

| Patents | |

| U.S. Patent #7,277,177 | |

Serani™ Analyzer Interface Software offers users a new way to access their analyzer remotely from any computer or laptop. Compatible with most HALO, Spark, Tiger-i, CO-rekt and ALOHA H2O series analyzers.