Furnacespection materials

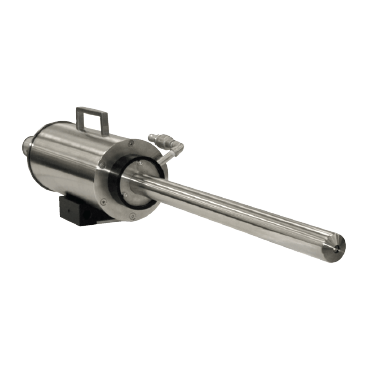

- Rugged IP66, air cooled, protective enclosure

- Accurate 640 x 480 focal-plane array thermal im- aging camera with sensitivity of 0.06 °C

- Ethernet interface for long distance reliable communication

- Boroscope optics filtered at 0.85 μm wave- length to view through combustion gas and flames

- Auto retraction for SD systems

- Class 1 Div 2 compliant

- Advanced software with simultaneous acquisition from multiple cameras, advanced analysis tools, support for OPC, analog and digital IOs, web service, and archiving

• Complete system integration with installation support

Description

This LumaSpectionTM system is designed and devloped for contin- uous temperature measurement inside high temperature furnaces in refining, metals, and glass production. FurnaceSpection’s proven technology provides critical insight for failure prevention and asset management.

The FurnaceSpectionTM imager provides users with a real-time tool for quickly and accurately identifing process abnormalities before they develop into problems that can lead to unplanned outages. This radiometrically calibrated imager accurately measures the temperature of product, refractory, and heat transfer surfaces inside natural

gas fired furnaces. In addition to both standard (SD) and mobile (MB) versions, we can customize a solution to meet your application needs.

For petrochemical reformers, this is a critical tool to ensure tubes perform optimally for their longest possible life cycle. At a cost of several thousands of dollars per tube and a re-tubing costs in the

millions, a significant amount of capital can be lost if tube failure goes unnoticed or tubes are retired too early or too late.

In metal annealing applications, FurnaceSpectionTM cameras have allowed users to reduce cycle times while at the same time improving quality and process repeatability.

FurnaceSpectionTM helps opera- tors monitor and control process temperature uniformity through streaming images and powerful software for analysis and historical trending. Digital and Analog outputs are available to broad- cast images of the plant’s local network.

Lumasense has been developing industrial grade thermal imaging solutions for over 20 years, and have deployed custom systems around the globe to monitor critical processes and assets in power generation, refineries, steel, paper, and glass plants. Our products are supported by experi- enced field service and application engineering team.