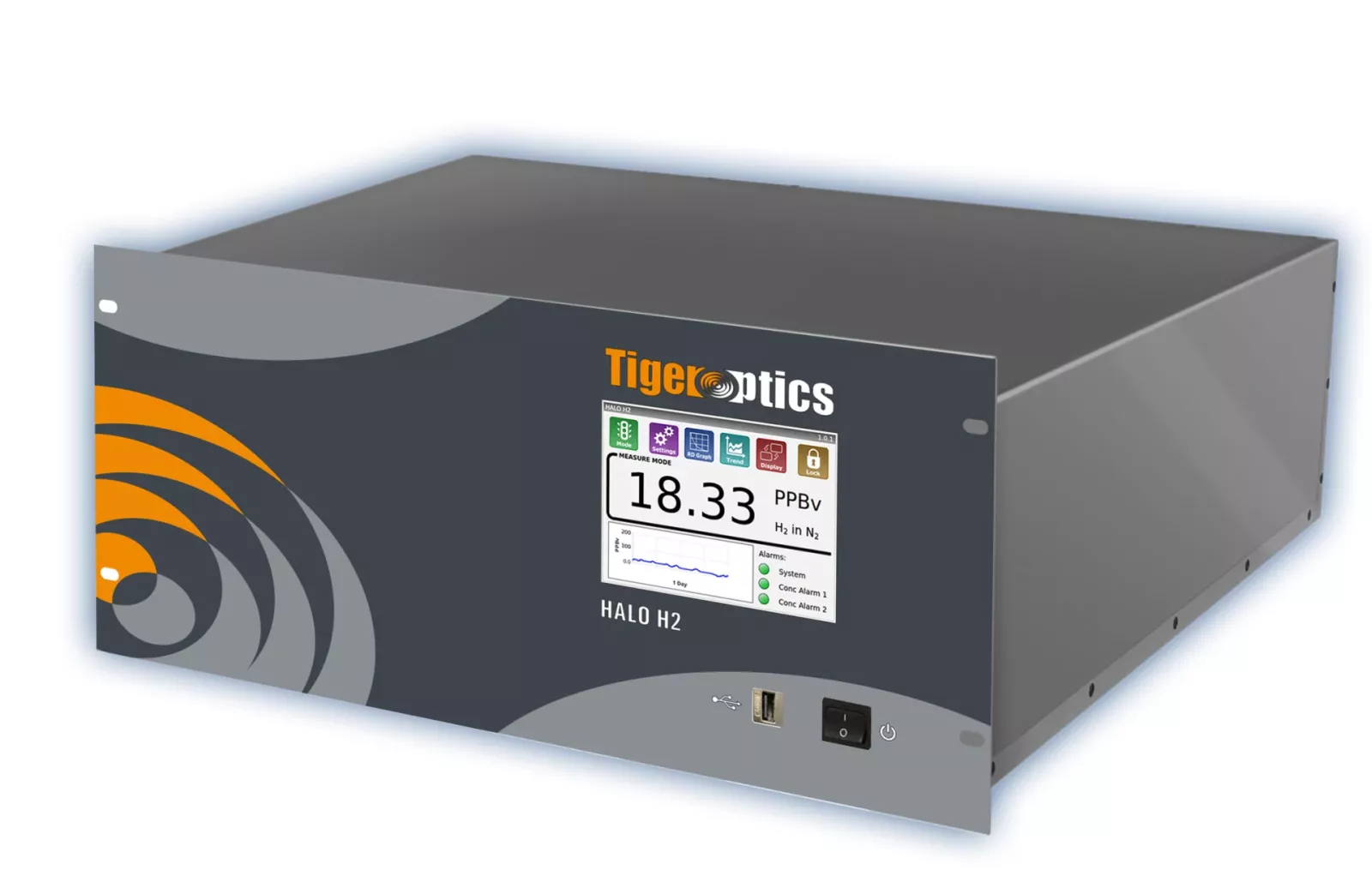

HALO™ H2

TIGER OPTICS™ CRDS Analyzer for ppb-level Hydrogen Detection

Description

CRDS LASER-BASED ANALYZER

LEADING CHOICE FOR ULTRA-HIGH PURITY GAS USERS

Detect gas quality upsets before they damage your process. Using our TIGER OPTICS™ HALO™ H2 analyzer, you can verify H2 impurity levels with part-per-billion accuracy, drift-free stability and instantaneous response. You will find our system exceptionally easy and fast to install, and effortless to maintain, with built-in zero verification. Its robust design—free of moving parts—results in an analyzer that has a high Mean Time Between Failure (MTBF) rate and a very low Cost of Ownership (CoO).With its patented catalytic conversion technique, utilizing a minute amount of oxygen to cleanly and safely convert hydrogen to moisture, the HALO H2 hydrogen analyzer offers a fully laser-based solution for continuous quality control of your process.

THE HALO H2 HYDROGEN ANALYZER OFFERS:

- Low parts-per-billion (ppb) detection capability with Standard Model

- NEW: Low-Range Model with parts-per-trillion (ppt) detection limits in inert gases

- Extremely fast speed of response

- Wide dynamic range

- Absolute measurement (freedom from need for calibration gases)

- Low maintenance and cost of ownership

- Compact, portable package, ideal for both fixed and mobile cart installation

- Direct measurement in many matrices, including oxygen

DETECTION CAPABILITY

| Detection and Matrix | Range | LDL (3σ) | Precision (1σ) @ zero |

|---|---|---|---|

| Standard Model (requires 1% O2, 99% N2 mixture or CDA utility gas) | |||

| H2 in N2 | 0 – 500 ppm | 8 ppb | 3 ppb |

| H2 in Ar | 0 – 200 ppm | 6 ppb | 2.0 ppb |

| H2 in He | 0 – 125 ppm | 4 ppb | 1.5 ppb |

| H2 in Ne | 0 – 140 ppm | 4 ppb | 1.5 ppb |

| CDA Model (requires pure N2 utility gas) | |||

| H2 in Clean Dry Air (CDA) | 0 – 5000 ppm | 80 ppb | 30 ppb |

SPECIFICATIONS

| Performance | |

|---|---|

| Operating range | See Detection Capability table |

| Detection limit (LDL, 3σ/24h) | See Detection Capability table |

| Precision (1σ, greater of) | ± 0.75% or 1/3 of LDL |

| Accuracy (greater of) | ± 4% or LDL |

| Speed of response | < 3 minutes to 95% |

| Environmental conditions | 10°C to 40°C, 30% to 80% RH (non-condensing) |

| Storage temperature | -10°C to 50°C |

| Gas Handling System and Conditions | |

| Wetted materials | 316L stainless steel, 10 Ra surface finish |

| Leak tested to | 1 x 10-9 mbar l / sec |

| Gas connections | 1/4” male VCR inlet and outlet |

| Sample inlet pressure | 10 − 125 psig (1.7 − 9.6 bara) |

| Sample flow rate | 0.5 slpm (± 20%) |

| Sample gases | Most inert matrices |

| Gas temperature | Up to 60°C |

| Utility gas supply* | see Detection Capability table for required gas |

| ~15 sccm, 20 − 125 psig | |

| Dimensions, H x W x D | |

| Standard sensor | 8.73″ x 19.0″ x 23.6″ (222 mm x 483 mm x 599 mm) |

| Weight | |

| Standard sensor | 45 lbs (20.4 kg) |

| Electrical and Interfaces | |

| Platform | Max series analyzer |

| Alarm indicators | 2 user programmable, 1 system fault, Form C relays |

| Power requirements | 90 − 240 VAC, 50/60 Hz |

| Power consumption | 200 Watts max. |

| Signal output | Isolated 4−20 mA |

| User interfaces | 5.7” LCD touchscreen, 10/100 Base-T Ethernet |

| USB, RS-232, RS-485, Modbus TCP (optional) | |

| Data storage | Internal or external flash drive |

| Certification | CE Mark |

| Patents | |

| U.S. Patent #7,277,177 • U.S. Patent # 7,255,836 | |

*Utility gas supply purity requirements: <10 ppm H2O and H2 impurities