HALO Max QCL™ CO

Categories: Process Insights, For Industrial Application, Dew Point Analyzers

Description

CRDS LASER-BASED GAS ANALYZER

EXPANDING OPTICAL CONTAMINANT DETECTION CAPABILITIES

Our NEW TIGER OPTICS™ HALO Max QCL™ allows dramatic decreases in detection limits for certain molecules, such as CO. The HALO Max QCL CO for ppt-level carbon monoxide detection is based on our latest Max platform, offers exceptional speed and further improved usability in an all-inclusive and robust package. The analyzer is fast to install, offers continuous, real-time detection, and is easy to use and effortless to maintain, with built-in zero verification and zero drift. The HALO Max QCL CO perfectly complement our HALO KA Max series (for H2O, NH3 and CH4), the HALO OK (for O2) and our other QCL-based analyzer, the HALO Max QCL CO2 to utilize the advantages of CRDS for detection of a large variety of critical trace impurities.

OUR FIRST ANALYZER SERIES BASED ON QUANTUM CASCADE LASER CAVITY RING-DOWN SPECTROSCOPY (QCL-CRDS), THE HALO MAX QCL CO OFFERS:

- Parts-per-trillion (ppt) detection capability for carbon monoxide (CO) in UHP bulk gases

- Incorporates mid-infrared QCL technology to achieve the ultimate sensitivity

- Absolute measurement (freedom from calibration)

- Excellent speed of response at ppb levels and below

- Continuous measurement—no batch processing typical with GCs

- Robust design & maximum ease of use

APPLICATIONS

- Gas Quality Control

- High-Purity Gases & Systems

- Research & Development

- Semiconductor Process Tools

DETECTION CAPABILITY

| Detection and Matrix | Range | LDL (3σ) | Precision (1σ) @ zero |

|---|---|---|---|

| CO in N2 | 0 – 0.5 ppm | 200 ppt | 70 ppt |

| CO in He | 0 – 0.35 ppm | 130 ppt | 45 ppt |

| CO in Ar | 0 – 0.4 ppm | 150 ppt | 50 ppt |

| CO in H2 | 0 – 0.5 ppm | 200 ppt | 70 ppt |

| CO in O2 | 0 – 0.45 ppm | 170 ppt | 60 ppt |

| CO in Clean Dry Air (CDA) | 0 – 0.5 ppm | 200 ppt | 70 ppt |

SPECIFICATIONS

| Performance | |

|---|---|

| Operating range | See Detection Capability table |

| Detection Limit (LDL) | See Detection Capability table |

| Precision (1σ, greater of) | ± 0.75% or 1/3 of LDL |

| Accuracy (greater of) | ± 4% or LDL |

| Speed of response | < 1 minute to 95% |

| Environmental conditions | 10°C to 40°C, 30% to 80% RH (non-condensing) |

| Storage temperature | -10°C to 50°C |

| Gas Handling System and Conditions | |

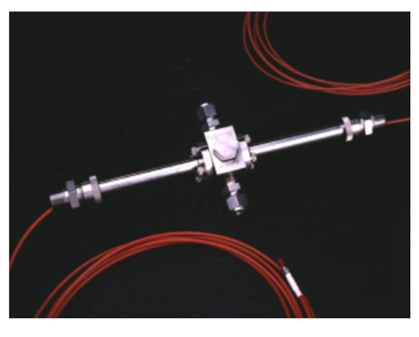

| Gas connections | 1/4” male VCR inlet and outlet |

| Leak tested to | 1 x 10-9 mbar l / sec |

| Inlet pressure | 6 − 125 psig (1.4 − 9.6 bara) |

| Flow rate | <1 slpm in N2 (gas dependent) |

| Sample gases | Most inert and passive gases |

| Gas temperature | Up to 60°C |

| Dimensions, H x W x D | |

| Standard sensor | 8.75″ x 19.0″ x 25.0″ (222 mm x 483 mm x 635 mm) |

| Weight | |

| Standard sensor | 55 lbs (25 kg) |

| Electrical and Interfaces | |

| Platform | Max series analyzer |

| Alarm indicators | 2 user programmable, 1 system fault, Form C relays |

| Power requirements | 90 − 240 VAC, 50/60 Hz |

| Power consumption | 100 Watts max. |

| Signal output | Isolated 4−20 mA |

| User interfaces | 5.7” LCD touchscreen, 10/100 Base-T Ethernet |

| USB, RS-232, RS-485, Modbus TCP (optional) | |

| Data storage | Internal or external flash drive |

| Certification | CE Mark |

| Patents | |

| U.S. Patent #7,277,177 | |

Serani™ Max Analyzer Interface Software allows you to have remote access from your computer or laptop for our latest CRDS generation analyzers, such as the Halo KA Max and T-I Max. The Windows-based software package communicates with the analyzer through Ethernet and allows full control of the system conveniently from your desk.