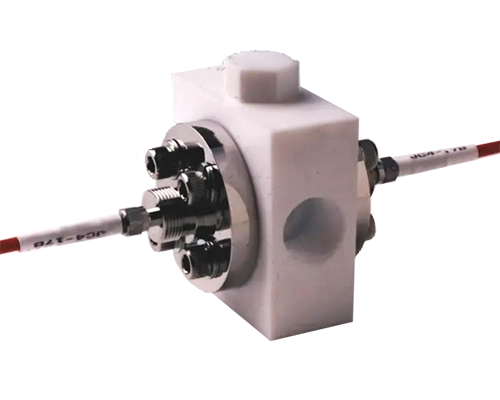

HEATED MULTI-PURPOSE FLOW CELL

GUIDED WAVE™ Flow Cell for Heating/Cooling Fluid to Maintain Temperature of Preconditioned Sample

Description

MULTI-PURPOSE HEATED FLOW CELL

Our GUIDED WAVE™ Multi-Purpose Heated Flow Cell is drilled to accept a heating or cooling fluid. While the heat exchanged is not sufficient to significantly impact a rapidly flowing sample, it can be used to maintain the temperature of a preconditioned sample. Our Multi-Purpose Flow Cell (MPFC) is used whenever direct insertion probes are not appropriate and the process material does not require the added assurance of the High Safety Flow Cell. One of the primary advantages of near infrared process spectroscopy is the utilization of intrinsically safe fiber optic cables to remotely locate the probe.

EXCEPTIONAL LIGHT TRANSMISSION AND OPTICAL PERFORMANCE

The GUIDED WAVE Multi-Purpose Heated Flow Cell provides exceptional optical performance. Typically, peak transmission exceeds 50%. That means more signal, lower measurement noise translating to lower limits of detection.

PROCESS-RESISTANT FLOW CELL BODY CONSTRUCTION

The GUIDED WAVE Multi-Purpose Heated Flow Cell comes standard in 316L stainless steel but is available in many other alloys. Suitable O-ring materials must be specified to meet your process chemistry and safety requirements. Common materials, such as Viton, Kalrez®, EPDM, etc., are readily available. Please consult appropriate resources for temperature specifications of various O-ring materials and chemical compatibility with your process.

A SIMPLE, SERVICEABLE FLOW CELL DESIGN

Key elements of the GUIDED WAVE Multi-Purpose Heated Flow Cell design are simple, serviceable O-ring seals, the clean-out port, high optical efficiency, slip jointed conduit-ready connections, sapphire windows, a clean flow pattern, and O-ring sealed optics to prevent ambient moisture infiltration. The probe can be field disassembled for O-ring service and reassembled without changing the optical path length, a crucial parameter for repeatable measurements.

- Suitable for many installations in side streams or sample conditioning systems

- Suitable for use where temperature control of sample is desired

- Threaded chamber is provided for the circulation of heating or cooling fluids

- Collimated beam for excellent light transmission

- Clean out port for easy window cleaning

- Compatible with all GUIDED WAVE analyzers

TEMPERATURE CONTROLLED FLOW CELL FOR AT-LINE FT-NIR MEASUREMENTS

GUIDED WAVE’S Multi-Purpose Flow Cell for FT-NIR analyzers is also available with internal tubing’s for heating or cooling fluid. While the heat exchanged is not sufficient to impact a rapidly flowing sample, it can be used to maintain the temperature of a preconditioned sample.

WHY CONTROLLING THE TEMPERATURE OF THE SAMPLE INTERFACE MATTERS?

Some applications such as nucleation reactions, polymer cross-linking or high viscosity fluids require that the temperature of the fluid be precisely controlled to ensure that the reaction proceeds as expected and passes through the flow cell. If the temperature drops, the fluid may solidify in the flow cell or the polymer chain may not be the correct length.

WHEN TO USE A FLOW CELL INSTEAD OF AN INSERTION PROBE?

The Multi-Purpose Flow Cell (MPFC) is used whenever direct insertion probes are not appropriate and the process material does not require the added assurance of the High Safety Flow Cell. One of the primary advantages of near infrared process spectroscopy is the utilization of

intrinsically safe fiber optic cables to remotely locate the probe. While direct insertion probes eliminate sample loops and sample systems and their associated problems, sometimes it is necessary to install sample loops for safety, service, and/or sample conditioning reasons. The MPFC is a convenient, compact, rugged sample interface that is easy to install and even easier to service. The cell’s sapphire windows can be cleaned by simply removing a clean-out plug for direct access to the windows without disconnecting process lines or fiber optic cables. This clean-out port is our innovation.

THE HEATED FLOW CELL IS COMPATIBLE WITH BRUKER MATRIX-F AND ABB FT-NIR SPECTROMETERS

The Heated Flow Cell is manufactured by Guided Wave to facilitate full integration with any fiber-optic spectrophotometer manufacturer. The heated Flow Cell is fully compatible with the Matrix-F FT-NIR analyzer, ABB’s full line of FT-NIR spectrometers, and AIT’s optical analyzers. The market leading optical efficiency of our sample interfaces will improve the optical performance any spectrometer when connected with 400 to 600 micron fiber optical cables and SMA 905 or FC connectors. The NIR-O Full Spectrum DG-NIR Spectrometer and Clearview DB photometer are the only analyzers engineered to be ‘’optically matched’’ with GUIDED WAVE probes.

EXCEPTIONAL LIGHT TRANSMISSION

Like other probes, the MPFC provides exceptional optical performance. Typically, peak transmission exceeds 50%. That means more signal, lower measurement noise translating to lower limits of detection. Buying our GUIDED WAVE probe will increase the performance of any spectrometer.

OPERATING RANGE OF THE HEATED FLOW CELL

• Temperatures to 300 °C (O-ring material dependent)

• Pressures to 500 psi (O-ring durometer dependent)

• A certified version is available that is rated to 1000 psi

This flow cell is available in five standard pathlengths 1, 2, 5, 10, and 20 mm.

DUAL SEAL FOR ADDED SAFETY

Our Multi-Purpose Flow Cells now boast a dual seal at the sapphire “window-to-process” interface. This doubles protection for the expensive internal optical lens.

- Suitable for many installations: side streams, sample loops, or sample conditioning systems

- Suitable for use where temperature control of the sample is desired

- Threaded chamber is provided for the circulation of heating or cooling fluids

- Collimated beam for excellent light transmission

- Clean out port for easy window cleaning

- Compatible with all makes and models of photometers and spectrometers

| Product Name | Heated Multi-Purpose Process Flow Cell |

|---|---|

| Optical Pathlength | 1; 2; 5; 10; 20 mm |

| Spectral Range | UV-VIS (200 – 600 nm); NIR (600- 2100 nm) |

| Fiber Connector | SMA 905 |

| Optical Efficiency | >45% transmission from 800 – 1650 nm (%T) |

| Temperature Range | ≤300 °C (O-ring material dependent) |

| Pressure Range | 0 to 500 psi [3450 kPa], (certified version rated to 1000 psi) |

| Body Material | 316L SS standard; Hastelloy C-276, others available on request |

| O-Ring Material | Viton, EPDM, Kalrez, silicon, other materials available upon request |

| Process Connection | 3/8 inch tubing (for pathlengths 1-5mm); 1/2 inch tubing (for 10mm pathlength); 1 inch tubing (for 20mm pathlength); 1/8 inch NPT ports for heating or cooling fluid |