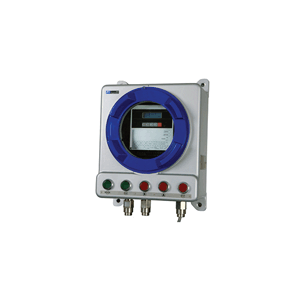

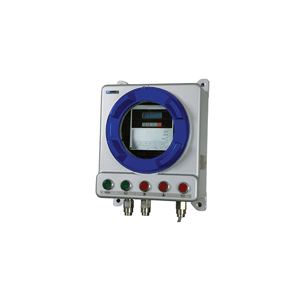

In-Situ Zirconia Oxygen Analyzer

Fast response + no sampling involved — ideal for combustion management in boilers or furnaces

Use of flow guide tube — low maintenance

Flameproof design — ideal for oxygen analysis in hazardous areas, for example, petrochemical plants

- Easily replaceable zirconia element

- Fast response: 4 s to 7 s

- Operation available without opening the cover

- TIIS and NEPSI flameproof certified

Categories: FUJI ELECTRIC, Analysers

Description

Specifications

General specifications

| Item | Specifications |

|---|---|

| Target | O2 in incombustible gas |

| Principle | Direct insertion zirconia sensor |

| Range | 0 to 2…50 vol% (user configurable two ranges) (in 1 vol% steps) |

| Repeatability | ≤ ±0.5% FS |

| Linearity | ≤ ±2% FS |

| Response time | 4–7 s for 90% response (from calibration gas inlet) |

| Warm-up time | Approx. 30 min (20 min when using ejector) |

| Analog output | 4–20 mA DC (allowable load resistance ≤ 500Ω) or 0–1 V DC (output resistance ≥ 100Ω) |

| Power supply | Rated voltage 100–120 V AC (operating voltage: 90–132 V AC) 200–240 V AC (operating voltage: 190–264 V AC) Rated frequency 50/60 Hz |

| Power consumption | Max. 240 VA Normal 70 VA |

Detector ZFKE

| Item | Specifications |

|---|---|

| Gas temperature | Flow guide tube type: -10°C to +600°C |

| Gas pressure | -3 kPa to +3 kPa |

| Operating temperature | -10°C to +60°C |

| Enclosure | Dustproof and rainproof, IEC IP66 equivalent |

| Weight | Approx. 3 kg (excluding the flow guide tube) |

| Ejector air inlet flow rate | 5 L/min to 10 L/min |

| Ex-proof standards | TIIS Ex d IIB T4 NEPSI Ex d IIC T4 Gb |

| Flow guide tube | With or without blow-down nozzle Flange: JIS 5K 65A FF or as specified Insertion length: 0.3, 0.5, 0.75, or 1 m |

Converter ZKME

| Item | Specifications |

|---|---|

| Contact output | 6 points, SPST, 250 V AC/3 A or 30 V DC/3 A (under maintenance, device error, alarm, zero calibration, span calibration, under blow-down) |

| Contact input | 3 points, ON: 0 V, OFF: 5 V, ≤ 10 mA (remote hold, calculation reset, heater OFF, blow down, inhibition of calibration, calibration start, range change) |

| Communication | RS232C (MODBUS) RS485 (MODBUS) (option) |

| Combustion efficiency display | (option) |

| Operating temperature | -20°C to +55°C |

| Enclosure | Dustproof and rainproof, IEC IP65 equivalent |

| Weight | Approx. 22 kg (excluding cable and detector) |

| Ex-proof standards | TIIS Ex d IIB T6 NEPSI Ex d IIC T6 Gb |