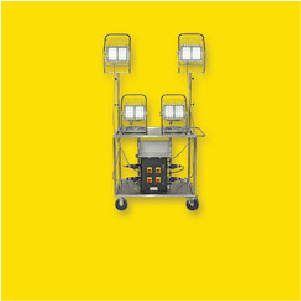

LAMP ANALYZER

EXTREL™ Quadrupole Mass Spectrometer

Description

UNMATCHED QUADRUPOLE MASS SPEC TECHNOLOGY FOR LAMP MANUFACTURING

Powerful Mass Spectrometer for Lamp Manufacturing Applications

Our EXTREL™ Quadrupole Lamp Analyzers have a long history of quality assurance measurements in Lamp Manufacturing. We have partnered with the major lamp manufacturers to engineer sampling solutions for hundreds of different lamp types has allowed us to become the premier supplier of fill gas analyzers to the lighting industry.

Our Quadrupole Lamp Analyzer combines our proven process mass spectrometry technology with a specially designed inlet to test a multitude of lamp configurations. It has automatic testing capability for multiple lamp designs, and it can switch from automatic to manual operation for special tests.

The modular design allows for analysis of different lamp types with the same instrument. The standard configuration of the Lamp Analyzer has four cassettes, each of which can hold eight small lamps. Once samples are loaded into the cassette, the analyzer will automatically break the lamps, flow the gas into the sample sink, and release the sample to the mass spectrometer for analysis. This automated analysis routine can be run for a single lamp or for all four cassettes: 32 lamps in total. The resulting analysis, gas pressure, and volume calculations are displayed in the user’s report.

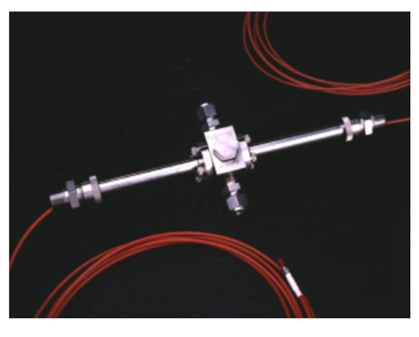

In addition to the basic standard configuration, Extrel has designed special sampling devices for other lamp types. Typically, these sampling arrangements replace one of the four standard cassettes. Our experience allows us to offer designs for new lamp types with ever-changing braking systems.

APPLICATIONS

- Lamp manufacturing

Mass Range

- From 1-250 amu (optional 1-500 amu) with the capability to monitor gases and vapors with fragment masses that fall within that range

Standard Dual Faraday/Electron Multiplier Detector Range

- From 10 parts per billion (ppb) to 100%

Dual Filament Ionizer

- One filament is utilized for operation while the second filament acts as a spare

- The system provides automatic filament switchover for continuous operation

High Compression Turbo Molecular Pump with Molecular Drag

- A “fail safe” interlock protects the system against a power failure or sudden vacuum loss. The vacuum chamber is also equipped with a vacuum gauge and an auto vent assembly.