TURBIDITY ANALYZER SYSTEM

GUIDED WAVE™ VIS-NIR Dual-Beam Photometer

Description

RELIABLE VIS-NIR DUAL-BEAM ANALYZER

A Cost-Effective Turbidity (Haze) NTU Analyzer System

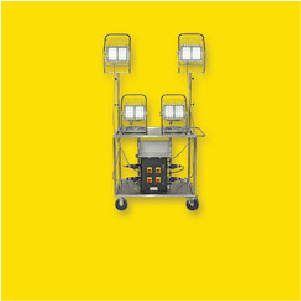

Our GUIDED WAVE™ Turbidity Analyzer System is a complete, “ready-to-go” analytical system.

- Analyzer – ClearView® db filter photometer

- Fiber optic cables

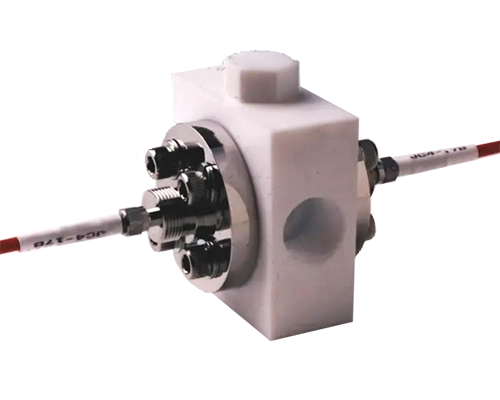

- Sample interface – insertion probe or flow cell

- Control software and Saybolt application calibration

- Accurate, Real-time Reliable Results

COMPLETE TURBIDITY NTU ANALYZER SYSTEM

Our GUIDED WAVE Turbidity Analyzer System utilizes our multi-wavelength ClearView db filter photometer analyzer platform. It may be configured for two (2) independent sample monitoring points. Turbidity can be measured on one channel only, leaving the second channel available for any other measurements such as color. The analyzer employs a dual-beam design – meaning; the system has a continual internal optical reference check that allows it to self-compensate for signal variation due to non-sample conditions. This ultimately provides the system with long-term stability. The final product is a total Turbidity Color System that measures the turbidity variation without interference from other factors.

- Unique dual beam optics – for long term, stable operation

- One turbidity channel plus another independent measurement point – for added analytical flexibility at reduced cost per point

- High efficiency yet rugged fiber optics – analyzer electronics can be located away from a hazardous sample point

- In-door touch screen or Ethernet (Modbus TCP) – easy local or remote analyzer operation and control

- Analytical calculations are all encoded in the software – answers and alarms are clearly reported

- Options for a Custom Solution

The ASTM method is a visual standard for measuring turbidity (caused by immiscible water in fuels) by viewing cards with black lines of various thicknesses through a 100mm diameter glass jar of solution. The result is a value (called Haze) between 1 and 6, with 1 being the clearest. Haze is typically measured in the refining sector and arises from water beyond the solubility limit. Alarming on this solubility issue allows the refiner to have better control of the fuel quality.

BENEFITS

The GUIDED WAVE Turbidity Analyzer System offers several benefits, including:

- Accurate and reliable results: The system uses state-of-the-art optics and detection technology to provide highly accurate and repeatable measurements of turbidity in liquids.

- Real-time measurement: The system provides real-time measurement of turbidity, enabling rapid process control and quality assurance.

- Non-destructive measurement: The system uses non-destructive measurement techniques, eliminating the need for sample preparation and reducing waste.

- Low maintenance: The system is low maintenance, with no moving parts and a long lifespan.

- Easy to use: The system is easy to install and operate, with user-friendly software and an intuitive interface.

- Versatile: The system can be used to measure turbidity in a wide range of applications, from drinking water to industrial process streams.

- Cost-effective: The system is cost-effective, with low operating costs and a rapid return on investment.

The GUIDED WAVE Turbidity Analyzer System is ideal for applications in the water treatment, wastewater treatment, and industrial process control industries, where the level of turbidity in liquids is an important indicator of water quality or process performance. The system is also suitable for use in the food and beverage industry, where turbidity measurement is important for quality control in products such as beer and juice.

INDUSTRIES

The GUIDED WAVE Turbidity Analyzer System is used in various industries, including:

- Water and wastewater treatment: The system is used to measure and control turbidity levels in water and wastewater treatment plants.

- Food and beverage: The system is used for quality control in the food and beverage industry to monitor turbidity levels in products.

- Chemical processing: The system is used in chemical processing industries to monitor turbidity levels in different processes and products.

- Pharmaceutical: The system is used in the pharmaceutical industry to measure the turbidity of solutions used in drug production.

- Mining: The system is used in mining industries to monitor the turbidity of wastewater and effluent streams.

- Environmental monitoring: The system is used for environmental monitoring in rivers, lakes, and other bodies of water to determine the level of turbidity and its impact on aquatic life.

APPLICATIONS

The GUIDED WAVE Turbidity Analyzer System is used in a variety of applications, including:

- Water treatment: The system is used to monitor and control the turbidity levels in drinking water, wastewater, and surface water treatment plants.

- Industrial process control: The system is used in a wide range of industrial processes where turbidity is a critical parameter, such as chemical processing, food and beverage production, and pharmaceutical manufacturing.

- Environmental monitoring: The system is used for environmental monitoring of rivers, lakes, and other bodies of water to determine the level of turbidity and its impact on aquatic life.

- Research and development: The system is used in research and development projects to study the effect of turbidity on different processes and materials.

- Quality control: The system is used for quality control in the food and beverage industry, where turbidity can affect the appearance, taste, and texture of products.

- Biotech and pharmaceuticals: The system is used to measure the turbidity of solutions used in biotech and pharmaceutical applications, such as cell cultures and protein solutions.