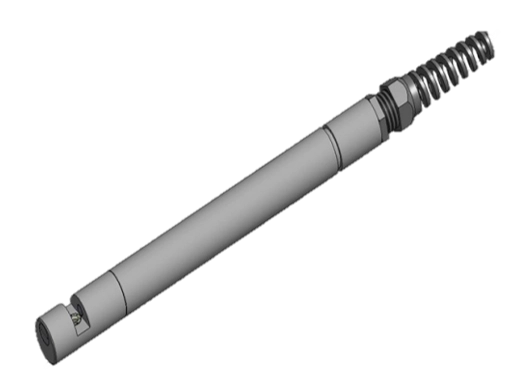

TURBIDITY PROCESS PROBE

GUIDED WAVE™ for Haze or Turbidity (NTU) Measurements with ClearView® db

Description

CORROSION-RESISTANT CONSTRUCTION YOU CAN TRUST

Our GUIDED WAVE™ Turbidity Process Probe is designed to withstand corrosive processes. The body of the probe is built from 316L stainless steel. The probe’s sapphire optical windows are sealed to the probe body with polymer O-rings chosen to be compatible with your process. On request, the Turbidity Probe can be supplied welded to an ANSI or DIN process flange. Like our other process probes, 24 inches or longer, it is also compatible with our probe extractor.

Our GUIDED WAVE Turbidity Process Probe with an additional third port can be used for Haze or Turbidity (NTU) measurements with our ClearView® db process photometer. The turbidity measurement detects solids breakthrough in your process while simultaneously measuring the transmission. The 20mm pathlength is appropriate, for example, when monitoring Saybolt color. One of the primary advantages of UV-Vis and NIR process spectroscopy is the utilization of intrinsically safe fiber optic cables to remotely locate the analyzer relative to your process. Inline probes eliminate costly and problematic fast loops and sample systems.

TURBIDITY PROBE FEATURES

- Corrosion resistant construction

- Rugged design

- O-ring process seals

- Sealed against ambient moisture infiltration

- High optical throughput for low noise spectroscopy

- Collimated beam for accurate absorbance measurements

- Vibration resistant design

- Haze or turbidity measurement is made by a 90° back scatter method. This function requires a third optical fiber to return the scattered light to the analyzer.

OPERATING RANGE AND CONFIGURATIONS

The operating range of the Turbidity Probe will be determined primarily by the choice of O-ring material. The maximum operating temperature and pressure are 250°C and 500 psi. This probe is available in five standard lengths, and UV, visible and NIR versions.

EXCEPTIONAL LIGHT TRANSMISSION

Our GUIDED WAVVE Turbidity Process Probe provides exceptional optical performance. Typically, peak transmission exceeds 25%. That means more signal, lower measurement noise, and lower limits of detection.

SPECIFICATIONS

| Product Name | Turbidity Process Probe |

|---|---|

| Probe Length | 12; 18; 24; 30; 36 (inches) other lengths available on request |

| Optical Pathlength | 20 mm |

| Spectral Range | UV-VIS (230 – 600 nm); NIR (600- 2100 nm) |

| Fiber Connector | 400; 500; 600 µm / SMA 905; FC |

| Optical Efficiency | >30% for pathlengths < 20 mm |

| Temperature Range | -20 to 250 °C (O-ring material dependent) |

| Pressure Range | 0 to 1000 psi [69 bar] |

| Body Material | SS316L standard (SS304, SS316, Hastelloy, Monel, Titanium, and Nickel available on request) |

| O-Ring Material | Viton, EPDM, Kalrez, Silicon, other materials available upon request |

| Window Seal | Polymer o-ring materials: Viton, Kal-Rez ® 6375, others on request |

APPLICATIONS

- Crude Oil Processing

- Water in Solvents

- Polyurethane Synthesis

- Caustic in Water

- Online Monitoring of Saybolt Color with a ClearView db Photometer

- Probes and Flow Cells for Extreme Environments

- Learn how our GUIDED WAVE RUGGED PROBES & FLOW CELLS MEET REFINERY REQUIREMENTS.

- Interested in learning more about our GUDIED WAVE PROBES & FLOW CELL SAFETY STANDARDS?

- Water Analysis in an Alcohol-Brine Solution with a ClearView db Photometer

- Water in Acetic Acid & p-Xylene with a ClearView db Filter Photometer

- Styrene, Acrylonitrile & Methyl-Ethyl-Ketone (Mek) for Online Control on a Styrene Tower

- Ensure Proper Ethylene Glycol Production Yields using NIR Technology

- Improve Yield During Diisocyanate & Urethane Synthesis

- Fast Reliable Measurements of Polyurethanes

- Probes & Flow Cells for Extreme Environments

- Probes and Flow Cells for High Temperature and Hazardous Polymer Measurements

- Inline Transmission Probe For FT-NIR Measurements

- Online Monitoring of APHA Color (ASTM D1209) with a ClearView db Photometer