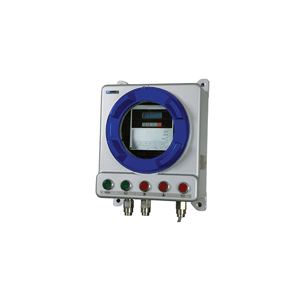

ZPAF Biomass Gas Analyzer

Measures H2S, CH4, CO2, and O2generated in biogas plants

- Simultaneous and continuous monitoring of H2S, CH4, CO2, and O2

- Compact and lightweight: 19-inch rack mount, 9 kg

- Easy-to-see LCD

- Optional functions include: automatic calibration, concentration alarm, remote input for switching range, and more.

- Small and lightThe size is small 133×483×418mm (H×W×D) and light (8kg).

But it is capable max. 5 component measurement in one analyzer. - Easy maintenanceBecause of single-beam system the measurement unit is simple with no need for optical adjustment. There- fore, maintenance is easy.

- Easy operationOperation can be carried out smoothly in an interactiveway through a large-size LCD.

- Abundant functionsVarious optional functions are available such as auto calibration control, high and low concentration alarm, remote range switch, and range identification signal, etc.

This gas analyzer (ZPAF) can simultaneously measure the concentration of CH4,CO2,H2S and O2 components in sample gas. CO2 and CH4 are measured by non-dispersion infrared method (NDIR), O2 is measured by fuel cell , and H2S is measured by constant-potential electrolytic method.

ZPAF provides high-stability and ease-of-maintenance incor- porated into a space-saving design. all these features make ZPAF ideal for biogas plants.

![]() ZPAF_Datasheet |

ZPAF_Datasheet | ![]() ZPAF_Catalog |

ZPAF_Catalog | ![]() ZPAF_Manual

ZPAF_Manual

Categories: FUJI ELECTRIC, Analysers

Description

Specifications

| Principle | CH4 & CO2: single-beam NDIR sensor O2: Galvanic cell sensor H2S: Constant-potential electrolytic sensor + Sample-switching system |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Display | 4-digit backlit LCD | |||||||||||||||

| Ranges |

|

|||||||||||||||

| Number of measurable components | Max. 4 (simultaneous and continuous measurement) | |||||||||||||||

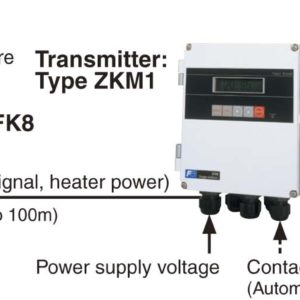

| Analog output | 4–20 mA DC or 0–1 V DC (up to 12 points) | |||||||||||||||

| Contact output (option) | SPDT relay contact (up to 15 points): device error, calibration error, range identification, auto-calibration status, solenoid valve drive for auto-calibration, limit alarm | |||||||||||||||

| Contact input (option) | Voltage contact input (12–24 V DC, up to 9 points) Remote switchover of ranges, auto-calibration remote start, remote hold |

|||||||||||||||

| Communication (option) | RS-485 (MODBUS) | |||||||||||||||

| Output hold | During calibration, output signal can be hold at the value before calibration. | |||||||||||||||

| Range switchover | Manual or automatic | |||||||||||||||

| Power supply voltage | 100–240 V AC, 50/60 Hz | |||||||||||||||

| Power consumption | Approx. 100 VA | |||||||||||||||

| Dimensions | H 133 × W 483 × D 382 mm | |||||||||||||||

| Ambient temperature | CH4 & CO2: 5–40°C H2S & O2: 15–40°C |

|||||||||||||||

| Weight | Approx. 9 kg | |||||||||||||||

| Gas inlet/outlet | Rc 1/4 or NPT 1/4 internal thread | |||||||||||||||

| Sensor life expectancy | O2 sensor: approx. 2 years H2S sensor: approx. 1 year |

|||||||||||||||

| Certification | CE Marking |

Performance

| Repeatability | ±0.5% FS (H2S: ±2.0% FS) |

|---|---|

| Linearity | ±1% FS (H2S: ±2.0% FS) |

| Zero drift | ±2% FS per week |

| Span drift | ±2% FS per week (H2S: ±2.5% FS) |

| Response time (for 90% response) |

10–30 s (H2S: 180 s) |

Gas conditions

| Flow rate | 0.5 ±0.2 L/min |

|---|---|

| Temperature | 10–50°C |

| Pressure | ≤ 10 kPa |

| Dust | ≤ 100 μg/Nm3 with particle size ≤ 0.3 μm |