Portable Ultrasonic Flowmeter

Excellent anti-bubble performance

Applicable pipe diameter: 13–6000 mm

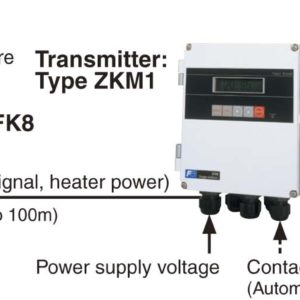

Flow transmitter (FSV)

Detector (FSS)

- High accuracy: 1.0% of rate

- Fast response: 0.2 seconds

- Compact transmitter: 142 x 170 mm

- Excellent anti-bubble performance

- Operation available without opening the cover

- RS-485 communication (option)

- Wide application range

- Parameter loader software provided

Categories: Ultrasonic Flowmeters, FUJI ELECTRIC

Description

| Fluid | Uniform liquid through which ultrasonic wave can propagate (deionized water, cooling water, chemical solution, tap water, etc.) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fluid temperature | -40°C to 200℃ (depends on detector) | ||||||||||||||||

| Applicable pipes |

Select FSSC for the following pipes:

|

||||||||||||||||

| Range | 0 to ±0.3…..±32 m/s | ||||||||||||||||

| Accuracy | ±1% of rate (when flow velocity is ≥2 m/s) | ||||||||||||||||

| Response | 0.2 seconds (in high-speed response mode) | ||||||||||||||||

| Ambient temperature | -20°C to +55°C (transmitter) -20°C to +60°C…80°C (depends on detector) |

||||||||||||||||

| Analog output | 4–20 mA DC, 1 point (maximum resistance load: 600Ω) | ||||||||||||||||

| Contact output | Open collector: 2 points Total, alarm, etc. Total pulse output: 1 P/day to 100 P/s (open collector) |

||||||||||||||||

| Serial communication | RS-485 (MODBUS) (option) | ||||||||||||||||

| Display | LCD with back light, 2-line 16-digit | ||||||||||||||||

| Key pad | 4 keys (ESC, up, shift, enter), Operation on panel (IP66 enclosure version) | ||||||||||||||||

| Power supply voltage | 100–240 V AC, 50/60 Hz, or 20–30 V DC | ||||||||||||||||

| Transmitter enclosure | Aluminum alloy, IP66 or IP67 | ||||||||||||||||

| Transmitter mounting | Wall mount or pipe mount | ||||||||||||||||

| Transmitter dimensions (in mm) | H170 x W142 x D70 (IP66) | ||||||||||||||||

| H220 x W230 x D95 (IP67) |